| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Certification : | ISO14001, ISO9001, UL, cUL, TS16949 |

| Price : | Customized |

| Payment Terms : | T/T, Western Union, paypal ect. |

| Supply Ability : | 60,000sqm per month |

| Delivery Time : | 1-15 working days |

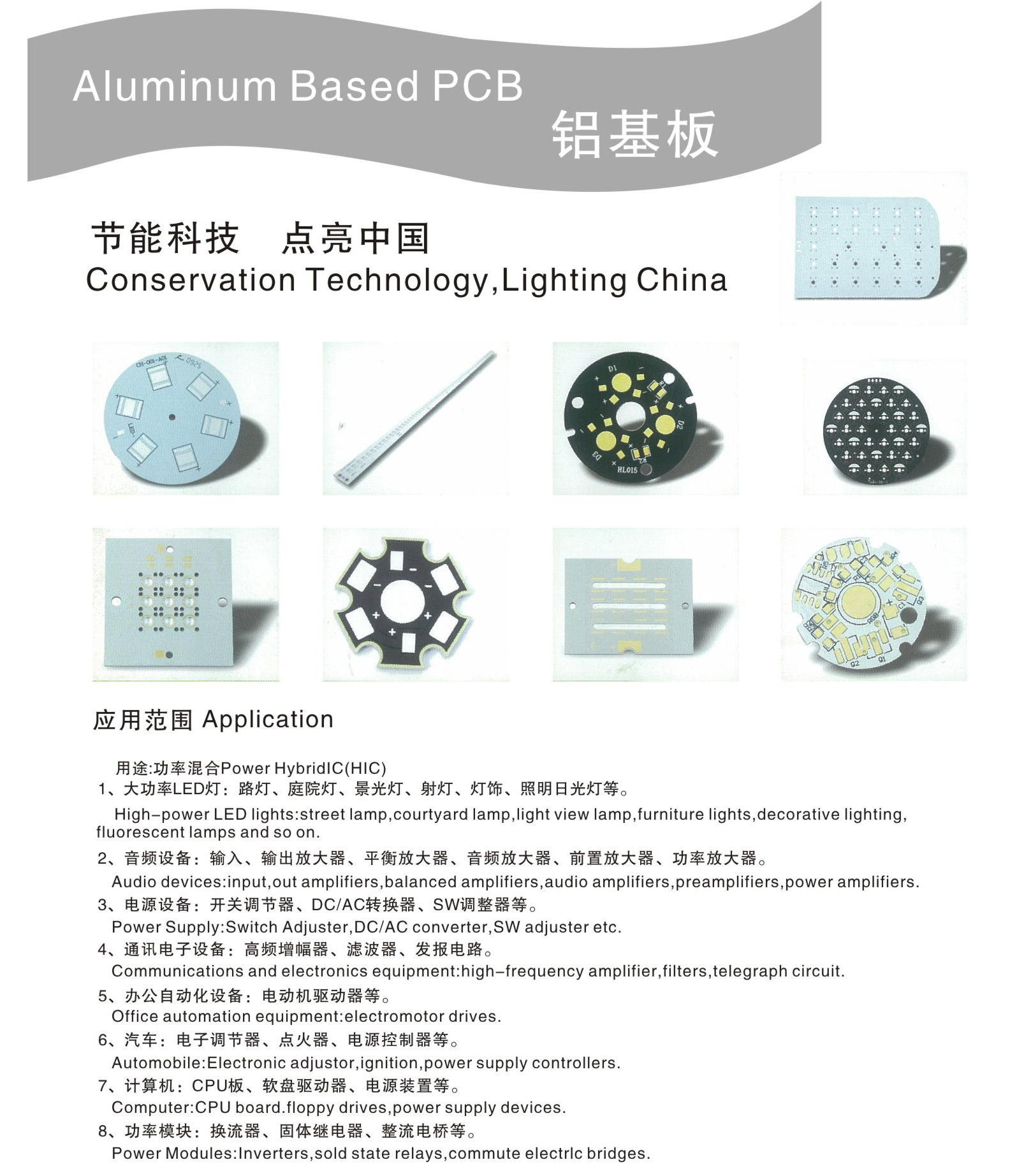

Printed Circuit Board for Led Lights, Metal Core PCB Board 1.2mm, 1.5mm, 2.0mm

Why is Aluminum used in LED light?

- The intense light produced by LEDs creates high levels of heat, which aluminum directs away from components. An aluminum PCB extends the lifespan of an LED device and provides more stability.

- Aluminum can actually transfer heat away from vital components, thus minimizing the harmful effect it could have on the circuit board.

How ABIS Working Out Manufacturing Difficulties of Aluminum PCB?

| Item | Spec |

| Layers | 1~20 |

| Board Thickness | 0.1mm-8.0mm |

| Material | FR-4, CEM-1/CEM-3, PI, High TG, Rogers, PTEF, Alu/Cu Base, etc |

| Max Panel Size | 600mm×1200mm |

| Min Hole Size | 0.1mm |

| Min Line Width/Space | 3mil(0.075mm) |

| Board Outline Tolerance | 士0.10mm |

| Insulation Layer Thickness | 0.075mm--5.00mm |

| Out Layer Copper Thickness | 18um--350um |

| Drilling Hole (Mechanical) | 17um--175um |

| Finish Hole (Mechanical) | 0.10mm--6.30mm |

| Diameter Tolerance (Mechanical) | 0.05mm |

| Registration (Mechanical) | 0.075mm |

| Aspect Ratio | 16:01 |

| Solder Mask Type | LPI |

| SMT Mini. Solder Mask Width | 0.075mm |

| Mini. Solder Mask Clearance | 0.05mm |

| Plug Hole Diameter | 0.25mm--0.60mm |

| Impedance Control Tolerance | 士10% |

| Surface finish | ENIG, OSP, HASL, Chem. Tin/Sn, Flash Gold |

| Soldermask | Green/Yellow/Black/White/Red/Blue |

| Silkscreen | Red/Yellow/Black/White |

| Certificate | UL, ISO 9001, ISO14001, IATF16949 |

| Special Request | Blind hole, Gold finger, BGA, Carbon ink, peekable mask, VIP process, Edge plating, Half holes |

| Material Suppilers | Shengyi, ITEQ, Taiyo, etc. |

| Common Package | Vacuum+Carton |

ABIS Circuits Co. Ltd, established in 2006, Located in Shenzhen, our company has about 1100 workers and two PCB workshops with about 50000 square meters.

Our products are mostly used in the field of Industrial Control,

Telecommunication, Automotive products, Medical, Consumer,

Security, and others.

| Year | Event | ||||

| 2006 | ABIS Electronics Founded, and Set up the factory in Shenzhen | ||||

| 2008 | Shenzhen Factory Put into Production and Passed the certification of Americal UL and ISO9001. | ||||

| 2009 | Shenzhen Factory got Canada UL.and Start to make 16 Layers in Volume | ||||

| 2010 | Overseas Sales Department ABIS Circuits Co.,Ltd established | ||||

| 2010 | Acquired the ISO14001 environmental management system certification | ||||

| 2012 | The manufacturing equipment was updated and a batch of cutting-edge manufacturing equipment was imported from Sweden, France, the United States, Germany, and other countries | ||||

| 2015 | We have a 30% investment in our Subcontractor in Jiangxi, No of Employees 1200 with 5000 square meters, the plant monthly product capability reached to 40,000m2 | ||||

| 2016 | The team was refined, and all staff participated in the development training to create a wolf team. | ||||

| 2017 | Attend Expo Electronica 2017/ electronica India | ||||

| 2018 | Attend Expo Electronica 2018/Electronica India | ||||

| 2019 | Attend Expo Electronica 2019/ Electronica India | ||||

FAQ:

Q1: How can I get a quotation:

. Please send Gerber file with format: .PCB / . P-CAD / .DXP / . Gerber

Q2: Can you manufacture my PCBs from a picture file?

. Could you please provide a sample?

Q3: Do you have PCB in stock?

. Most of our PCB board are customized, which according to Gerber file.

. ABIS has samples in stock that could be sent to you for quality

checking always.

Q4: What board manufacturer do you use for FR4?

. Main Suppliers(FR4): Kingboard (Hong Kong), NanYa (Taiwan), and

Shengyi (China).

Q5: Will my PCB files be checked?

. Checked within 12 hours. Once Engineer's question and working

file be approved, production will start.

Q6: What do you require in order to produce an assembly quotation?

. Bill of materials (BOM) detailing:

a), manufacturers parts numbers,

b), components suppliers' parts number (e.g. Digi-key, Mouser, RS )

c), PCBA sample photos if possible.

d), Quantity

ABIS cares every your order even 1 piece

|